Lamborghini Invencible and Autentica are its final NA V12 cars

A few months ago, we wrote that the final production units of the Lamborghini Aventador Ultimae represented the end of the reign of the naturally aspirated V12 in Sant’Agata Bolognese, and the last Aventador Ultimae meant the end of an NA V12 Aventador. Seems we were mistaken. Lamborghini now tells us these two one-offs are the proper and (maybe) final end of the NA V12. Created for a customer who worked with Lamborghini Centro Stile from inception, the duo are the Invencible (the Spanish spelling of “Invincible”) coupe and Auténtica roadster.

They’re not only farewells, they are greatest-hits compilations said to combine design features from the Reventón from 2008, the Sesto Elemento from 2010, the Veneno from 2013, and the 830-horsepower Essenza SCV12 track-only coupe from 2020. Lamborghini didn’t mention the Sián FKP 37, but the headlights are a match, and the side vents are a mix between the Sián and the Sesto Elemento.

Both are based on the Aventador’s carbon fiber tub, and both feature a 6.5-liter V12 making 769 horsepower and 531 pound-feet of torque.

The Invencible wears carbon fiber panels in Rosso Efesto, which is Hephaestus Red, Hephaestus being the Greek god of things like fire and volcanoes. The paint’s accented with carbon-look elements that glint with red flakes, brake calipers in Rosso Mars, and pure carbon. The hexagonal Tricolore on the door fits in with numerous other six-sided elements like the DRLs, three-part taillights, and exhaust. A tidy, angular swan-neck wing hovers over the rear fascia, its stanchions anchored beside the backlight.

Inside is a mix of Rosso Alala leather, Nero Cosmus Alcantara, and contrast stitching in Rosso Alala and Nero Ade. Rosso Efesto is used on the steering wheel and for the shift paddles. Designers removed the Aventador’s infotainment screen, moving all readouts to the digital gauge display and leaving twin hexagonal vents to dominate the open space over a pocket trimmed in red.

The Auténtica roadster is painted in Grigio Titans with details in Giallo Auge (Yellow Peak) and Matte Black. Instead of the Invencible’s rear wing, a pair of fins highlighted by a yellow line channel air over the rear spoiler. Inside, occupants sit on Nero Ade leather and Giallo Taurus stitching, and can ogle two-tone Nero Cosmus and Grigio Octans Alcantara.

This is really it for the V12. We think. The next engine out of the Sant’Agata gates will be the Aventador’s V12 hybrid successor, which Lamborghini says it only a few weeks away.

Related video:

Lamborghini applies to trademark V12 hybrid sounds in EV mode

Lamborghini is sprinkling various European intellectual property offices with bits of its future V12 super sports car it wants to protect. The internet continues to dig those bits up. After a couple of spy specialists found line drawings of the hybrid V12 coupe filed with the World Intellectual Property Office in North Macedonia, CarBuzz dredged up a sound clip of the V12 in pure electric mode filed with the European Intellectual Property Office. Spy shots have showed the car will come with a City Mode that’s expected to enable battery-only motivation. The audio clip appears to present three modes of the electric driving sounds required of all electric-capable vehicles to warn pedestrians of the EV’s approach.

CarBuzz believes the first sample was made under steady-state driving. It sounds a little like dark ambient ASMR with some wind in the background, like something from Atrium Carceri or Metatron Omega. The second would be under acceleration, the sinister electric symphony rising in pitch then fading as the unheard V12 internal combustion engine takes over. The last clip would be the reverse, as the V12 gives way to the battery again.

There’s nothing amiss in any of the sounds, but we find ourselves thinking there’s nothing especially Lamborghini about them, either. That’s not a slight against the crew from Sant’ Agata, that’s a statement about what the future of hybrid and electric supercars could mean to us everywhere outside of a highway or Cars and Coffee. It could make Dodge’s Fratzonic Exhaust that much more interesting assuming the production sonics match what we’ve been told, and a recent Ferrari patent shows a rival group of Italians trying to forestall roads full of computer monitor noises with a “sonority current.”

2024 Chevrolet Corvette E-Ray prices top out at $122,245 before options

GM Authority dug up the price list for the 2024 Chevrolet Corvette E-Ray. As with the performance specs and base price we reported earlier, the trim walk stays in sight of the enthusiast special Z06, but the MSRP gap grows the further one climbs the six-figure ladder. The spec recap is: A 6.2-liter V8 powering the rear wheels with 495 horsepower and 470 pound-feet of torque, and an e-motor turning the front wheels with 160 hp and 125 lb-ft. Combined output hits 655 hp, a tiny stable shy of the 670-hp Z06, combined torque around 595 lb-ft, at least 100 lb-ft more than the Z06. Instant torque, an E-Ray-specific tune for the eight-speed dual-clutch automatic transmission, and four scrabbling tires mean the E-Ray beats the Z06 to 60 miles per hour by 0.1 second, doing the deed in 2.5 seconds. The E-Ray’s quarter-mile takes 10.5 seconds at 130 mph, another 0.1-second improvement over the Z06.

We’re not sure which tires GM used for the tests, but the differences could be larger even though the E-Ray weighs 274 pounds more than the Z06. Both cars get the same sizes of rubber, the Z06 coming on Michelin Pilot Sport 4S tires, the E-Ray coming on Michelin Pilot Sports, with the 4S versions optional.

MSRP’s for the E-Ray including the $1,395 destination charge applied to all 2023 Corvettes is:

- 1LZ Coupe: $104,295

- 1LZ Convertible: $111,295

- 2LZ Coupe: $109,795

- 2LZ Convertible: $116,795

- 3LZ Coupe: $115,245

- 3LZ Convertible: $122,245

The same bracket for the 2023 Z06 starts at $106,695 for the 1LZ Coupe and maxes out at $127,545 for the 3LZ Convertible before options. As the marketers would say, the more you spend on an E-Ray, the more you save compared to the Z06.

Yet, consider what might be a better example of Corvette progress: When we tested the then-new C6 Corvette ZR1 in 2009, that car’s base price after destination was $102,450, which paid for a supercharged 6.2-liter V8 making 638 hp and 604 pound-feet of torque that could hit 60 mph in 3.4 seconds and do the quarter in 11.3. The U.S. Bureau of Labor Statistics Inflation Calculator tells us that $102,450 in May of 2009 is $142,309 today. The bad news is that the inflation figure is the most upsetting stat in this post. The good news is that for the equivalent of $38,000 less, a Corvette buyer can get an all-wheel drive coupe that is quite a bit better in every way than the 2009 ZR1, and when considering the interior, massively better than any previous Corvette. It’s good times for those who can afford it.

Related video:

Lamborghini’s upcoming V12 hybrid leaked in patent images

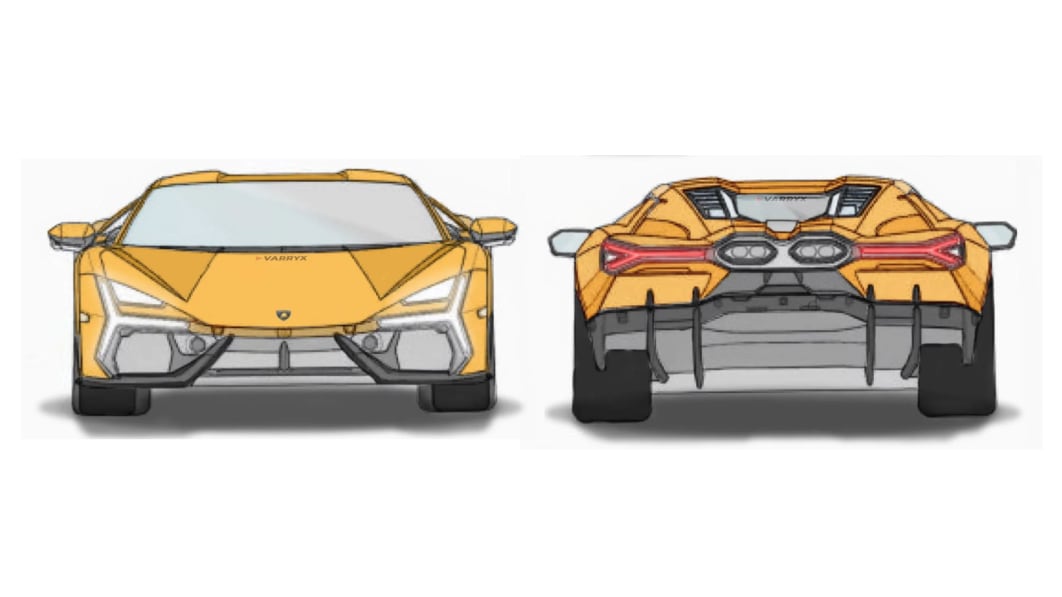

Varryx and Wilco Block are two Euro-based car enthusiasts we’ve come to know mostly for their ability to get spy video and images of coming treats. They’ve both done it again, both on Instagram, and both with the same car, publishing a series of design patent drawings. Lamborghini Automobili SpA submitted figures of its hybrid V12 successor to the Aventador to the North Macedonian bureau of the World Intellectual Property Office, perhaps hoping the out-of-the-way geographic location would translate to an out-of-the-way digital sequestration before the reveal this spring. But the Internet hates keeping secrets, so here we are. What we’re privy to are every major angle of a coupe that looks like it has the design of the Aventador as its foundation, bookended by fascias from a couple of Aventador-based specials. Varryx provided the colors for the image above.

Lamborghini said design of the Sián FKP 37 “is just for the Sián.” Fundamentally, perhaps, yes. But in the patent images, the tall, horizontal-y-shaped lighting DRL that welcomes the sharp, pincer-like curve of the front fenders, and the lower intake outlines make clear connection to the Sián. The Huracán Tecnica is the bridge, the V10-powered coupe adopting another take on the Sian’s style. The vertical spat behind the front wheels could also trace its lineage from the limited edition super sports car. The rest of the middle is all Aventador, a swelling body and large side intakes embracing the low cabin and naturally aspirated V12. In back, it’s the Centennario, a special edition introduced at the 2016 Geneva Motor Show. The six long strakes on the immense diffuser mimic the number on the Centennario, the difference being the coming production car moves its exhaust up high, where two Centennario taillights flank with two large hexagonal ports instead of the show car’s three small tips down low.

That engine will be an all-new V12 unit in a new drivetrain, we’ve been told, aided by a small battery and some supercapacitor tech that’s another nod to the Sián. Total output’s a mystery, but the Aventador Ultimae clocked 769 horses, the Countach 800 horses, and those not only didn’t have hybrid help, they were lighter. Fear not about the weight, automaker CEO Stephan Winkelmann says drivers won’t feel the additional weight. We wouldn’t be surprised to hear a number higher than 800. The transmission adds a clutch to the Aventador’s one, sending power through a dual-clutch system that will eliminate the Aventador’s characteristic tidal motion especially at low speeds. Preliminary performance specs outed by the chief estimate a 0-62 time under 2.9 seconds and a top speed beyond 218 mph.

The interior will carry on with a digital gauge cluster and add another screen to the center console. A City driving mode will activate pure-electric driving.

Expect a debut in March. Lamborghini says there are already 3,000 buyers in line, so set your sights on the second model year.

Related video:

Aston Martin DBS 770 Ultimate is a little more powerful, different looking

Aston Martin is bringing this iteration of the DBS sports car to a close, so of course it’s doing so with one more special edition: the DBS 770 Ultimate. It is one of the most powerful versions of the car, and has a selection of unique features. And like so many other special high-end sports cars, every example has been sold.

The headlining feature of the 770 is its extra power. It makes 759 horsepower, 44 more than the standard version, and basically the same as the DBS GT Zagato. Torque remains the same, though. A tweaked intake and ignition system plus 7% more boost pressure is responsible for the extra power. Top speed has not increased, though, sticking to 211 mph.

There are other light upgrades both performance-wise and design-wise. Additional vents have been added to the hood and a new splitter added to the front; both modifications are meant to improve cooling. More carbon fiber trim on the outside along with side sills, a diffuser, and unique wheels make it look more aggressive. The steering column has solid mounts for better steering feel. The front end is 25% stiffer than before, and the whole car is stiffer by 3% thanks to a redesigned front subframe and rear undertray. The transmission and adaptive suspension have been retuned, too. But it has the same carbon ceramic brakes and mechanical limited-slip differential as the regular car.

The interior gets some attention, too. The standard seats are Sports Plus units with more aggressive ones available. A special strap and buckle have been added to the center console. Of course, the interior and the exterior can be further customized with different colors, materials, graphics and more.

As previously mentioned, every DBS 770 Ultimate has already been sold. Only 499 will be built, 300 of which are coupes and 199 are convertibles. Aston didn’t give a price, which is understandable when it’s not even really on sale in a traditional way. But we’re sure each one will go for a fair premium over a standard model. Production starts soon, with deliveries coming in the third quarter of this year.

Related video:

Refreshed Aston Martin DB11 appears in spy photos

At nearly 7 years old, the Aston Martin DB11 is starting to show its age, so it makes sense that we’d see at least an updated version like the one in these spy photos. They show a thinly disguised coupe, and the design revisions are pretty minimal, too. But they should come with some useful upgrades under the new body.

The front fascia is really about all that’s changed on this car. The front grille is much larger, extending farther down and farther to each side than on the current DB11. The old slatted grille is gone, too, in favor of a very large egg-crate mesh. It looks as though the headlights may be updated, too, but it’s a bit difficult to tell for sure. As for the rest of the car, it’s pretty much identical to the current car.

This is all in keeping with the report last February that the entire Aston Martin lineup would be updated, and not just stylistically. Powertrain updates are apparently coming, with hybrids on the horizon. Nothing on this car indicates it’s a hybrid, though, and the hybrids are probably another year out. Odds are, we’ll see more powerful versions of the base AMG twin-turbo 4.0L V8 and the Aston twin-turbo 5.2L V12 first. Additionally, updated infotainment systems and interior upgrades will be reportedly be part of the refresh.

Last year’s report said the updated Astons would be launching this year. This prototype does look very close to production-ready, so that timeline still seems likely. And with it being Aston’s 110th anniversary, it’s a great time to start rolling out fresher product.

Related video:

Hennessey Venom F5 Revolution Coupe coming to a track near you

Hennessey isn’t finished milking the Venom. The Texas performance shop revealed the Venom F5 Coupe in December 2020, the Venom F5 Roadster in August of last year, and is kicking off 2023 with the Venom F5 Revolution Coupe. In Hennessey’s hierarchy of speeds, the original car was engineered to reach the highest production-car top velocity; the Roadster that followed was engineered to provide the most visceral experience; this F5 Revolution was made to master the track. Worked up from the initial F5 Coupe, the F5 Revolution gets the same basic goodies — carbon tub, 6.6-liter twin-turbocharged V8 with 1,817 horsepower and 1,193 pound-feet of torque, seven-speed automated single-clutch sequential transmission, carbon ceramic brakes. Hennessey says “the engineering team focused on reducing mass” so that the newest trim is the lightest Venom model and “tips the scales below 3,000 pounds.” However, the the F5 Coupe is already less than 3,000 pounds and company didn’t specify a new weight.

There are plenty of verifiable changes, though. A reshaped carbon fiber front splitter pairs with dive planes at the leading corners. A roof scoop shoves air into the mid-engine bay for enhanced cooling. The stand-up, adjustable carbon rear wing with endplates is claimed to shove more than 800 pounds of downforce on the rear axle at 186 miles per hour and more than 1,400 pounds of downforce at 249 mph. For those keeping track of the high-speed testing, Hennessey said the standard coupe hit 271.6 mph in March at the Johnny Bohmer Proving Ground. This one will be a touch less alacritous because of the appendages, but few owners will reach even 249 mph unless they end up at a Spa-Francorchamps track day.

Internal changes include a new transmission calibration, a more aggressive suspension setup, adjustable dampers, and wider forged alloy wheels making a larger contact patch. An available telemetry package displays and records circuit data including lap times, splits, and G-force.

The cost: $2.7 million, which is $600,000 more than the coupe, $300,000 less than the Roadster. We’re told it’s limited to 24 units, but our Spidey sense tells us that Hennessey calling this the Venom F5 Revolution Coupe points to a Venom F5 Revolution Roadster heading this way at around 250 mph. Anyone in southern Florida next week can see this family member make its debut at the Miami Motorcar Cavalcade Concours d’Elegance on January 15, 2023.

Related video:

Alfa Romeo teases 6C supercar taillight

Alfa Romeo’s latest reboot takes its next steps this year with the arrival of the refreshed Giulia and Stelvio to the U.S. market, and the debut of the new Tonale. The Italians primed the pump with an Instagram video celebrating 2022 and asking if we’re ready for 2023. At the end of the vid, Alfa Romeo answers its own question with, “We Are.” And as it’s clear to see, the first “e” is a brand new font we’ve not seen Alfa use before. Everyone expects this is a taillight from the supercar that brand chief Jean-Philippe Imperato starting hinting about last year, intel coalescing around the name 6C. If that ends up being the name, the new supercar would complete the trilogy of 2007’s 8C and 2015’s 4C.

If Evo can be believed, the 6C will borrow much of its tech spec from the Maserati MC20. Even more unexpected, Evo says Alfa Romeo will advertise the halo as a bridge between its internal combustion era and its electric era, so the supercar will be offered with ICE and EV powertrains. An electric MC20 is on the way, so the plan won’t be a tough jump. The most unexpected bit is when Evo says the Alfa Romeo supercar will use Maserati’s in-house Nettuno V6 designed for the MC20, whereas most believe Alfa plans to go with the 2.9-liter V6 used throughout its lineup and in other halos like the Giula GTA/Am. If Evo is correct, this is sounding like another 8C, that car based on the Maserati GranTurismo and using Maserati’s Ferrari-based engine of the time.

It’s a bit of a challenge to reconcile Evo’s report with some aspects of what Imperato said in an interview with Autocar. The honcho told Autocar, “It’s 1969 [the Spider] since the last time Alfa Romeo was stamped on a chassis” and it would be “a cool thing” to see again under his watch. We don’t envision that happening to the Dallara carbon fiber monocoque chassis designed for the MC20. Imperato also said the automaker’s still fine tuning the business case and that “the positioning is ongoing.” If Alfa Romeo were nabbing the $260,000 MC20 practically wholesale, the only positions are super spendy supercar and wildly spendy supercar. Lastly, the all-electric MC20 Folgore isn’t expected until 2024, the Alfa supercar at the end of 2023. It’s hardly believable Alfa Romeo would be allowed to electrify that chassis before Maserati had a chance to get it out and crow about it.

Whatever Alfa’s new halo ends up being, Imperarto said he’d like to tell the world about it in March.

Back with the regular range, Autocar said that from this year, every year that Alfa posts good numbers will unlock the ability to introduce a new model on top of the ones already planned through 2027. The current product plan includes the crossover below the Tonale in 2024, otherwise known as Alfa’s version of the European-market Jeep Avenger, as well as a larger SUV thought to replace the Stelvio in 2026. and a new-generation Giulia in 2025. For the boss, annual success means the chance to please Alfisti with products like a new Spider or Duetto — although they’d be all-electric.

Related video:

Join us for a closer look at the Lamborghini Huracan Sterrato

Unveiled in November 2022, the Sterrato is the final and arguably wildest evolution of the Lamborghini Huracán. The limited-edition coupe isn’t scheduled to enter production until February 2023, but Autoblog got to check it out in the flesh at a preview event held in Denmark.

The first all-terrain variant of the Huracán looks just as cool in person as it does in Lamborghini’s official photos. Seeing it up close reveals some of the finer design details that the press shots didn’t show, like the subtle “Sterrato” logo on both roof rails and the exposed bolts that hold on the wheel arch flares. I also got to take a peek in the engine bay for a look at the other side of the roof-mounted intake system.

While the Huracán STO also features a roof-mounted scoop, it’s used to channel cooling air into the engine bay. Rouven Mohr, the head of Lamborghini’s research and development department, told Autoblog that his team re-imagined the scoop as the intake system’s inlet after realizing that dust clogs the air filters via the stock, side-mounted intake system. While that’s not a huge deal in Los Angeles traffic, it’s important off the pavement because the Sterrato’s purpose isn’t to crawl over boulders; it was designed to go very fast on unpaved surfaces.

“Its purpose is fast off-roading,” Mohr told me. “In my mind, off-road you’re always going a little bit slow and climbing up somewhere. This is not the intention; this car can also climb but its intention is going sideways on gravel, rally-style.”

Zooming out, the Sterrato is a racing livery away from looking like a rally car. It’s considerably taller than the other Huracán variants, and it looks even higher in person than it does in photos. If you see it in the right light you can spot some of the underbody hardware between the wheels and the arches in spite of the meaty tires. The side skirts and rear diffuser have been given a more off-road-ready design as well.

We’ll need to be patient to find out what the Sterrato is like to drive, but it’s a recipe for fun on paper. It’s powered by a version of the STO’s naturally-aspirated, 5.2-liter V10 engine that develops 610 horsepower at 8,000 rpm and 417 pound-feet of torque at 6,500 rpm; the revised intake system is to blame for the 21-horse drop. Lamborghini quotes a 3.4-second sprint from zero to 62 mph and a top speed of 162 mph.

Lamborghini Huracán Sterrato production is limited to 1,499 units globally and once they’re gone, they’re gone; Mohr confirmed that a convertible version of the car isn’t in the pipeline. Act fast if you want one: I’m betting that the full run will be spoken for quickly.

Related Video

2023 McLaren Artura recalled for fuel leak-related fire risk

McLaren has issued a recall that applies to more than 150 units of the Artura, its new hybrid supercar. The vehicles included in the campaign are fitted with high-pressure fuel lines that can loosen, leak, and ultimately cause a fire because they’re not secured with the right hardware.

Assigned recall number 22V-908 by the National Highway Traffic Safety Administration (NHTSA), the campaign includes 164 examples of the Artura built from October 8, 2021, to November 14, 2022. Affected VINs range from SBM16AEA3PW000177 to SBM16AEA1PW000372.

McLaren explained that the recalled cars were built with high-pressure fuel lines held on by cold-formed nuts; the examples that are not part of the recall were manufactured with fully-machined nuts. It added that cold-formed nuts can loosen from the fuel pump over time, especially “during dynamic driving maneuvers commonly associated with track running.” In turn, this can create a fuel leak which increases the risk of a fire. McLaren noted that two cars developed a fuel leak on a track but adds that there are no injuries or accidents related to the defect.

Owners of affected cars will need to take their Artura to the nearest McLaren dealership to get the fuel pipes replaced free of charge. As for the root of the problem, the British company stated it switched to cold-formed nuts in March 2021 due to a shortage of fully-machined parts.

Related Video:

McLaren sells historic cars to raise cash to fund Artura upgrades

Cash-strapped McLaren Holdings Ltd. has recently sold some of its prized heritage car collection to Bahrain’s sovereign wealth fund Mumtalakat Holding Co. to raise capital.

The supercar maker was forced to seek an injection of funds after identifying “certain technical upgrades” on its Artura hybrid supercar that triggered delivery delays, McLaren said earlier this week during its third-quarter earnings. Its main shareholder — with Mumtalakat owning a near 60% stake — agreed to support the company with an additional £100 million ($123 million), the company said.

A McLaren spokesman confirmed the sale of some heritage vehicles to the company’s main shareholder in return for the cash infusion, without elaborating on the details of the cars sold.

McLaren’s heritage vehicles count 54 rare Formula 1 racing cars and F1 supercars, according to its 2021 annual report. The same report states that the company sells cars from its collection from time to time.

“We are in active talks with all shareholders regarding a recapitalization of the group,” McLaren said on the call, indicating the additional funds won’t be enough. It’s also continuing talks for potential partnerships.

McLaren reported a loss of £203 million in the nine months through September, compared with a £69 million loss a year ago. Liquidity at the end of the third quarter declined to £87 million, down from £171 million.

The British marque has sought emergency financing multiple times over the past few years from shareholders amid long delays in the launch of the Artura. The latest round of fundraising comes just months after its shareholders — which also include investment firm Ares Management Corporation and Saudi Arabia’s Public Investment Fund — gave £125 million through convertible preference shares.

Related video:

Bertone wants to make wedges great again

Of all the unheard-of brands being resurrected every day, here’s one we’re interested in. Bertone is on the way back after a couple of decades of rough going. Giovanni Bertone founded the Italian design house in 1912, but it was the postwar years while being run by Nuccio Bertone that the company penned one legend after another. Lancia Stratos, Lamborghini Miura and Countach, Ferrari Dino 308 GT4, Fiat X1/9, and so on. A 2014 bankruptcy led to being bought by Mauro and Jean-Frank Ricci, brothers who own an auto industry consultancy called Akka that’s worked with Aston Martin, Ford, and the Volkswagen Group. Their only public showcase with Bertone so far was the 2016 Smart Bertone, an electric two-seater with more than three times the horsepower of the standard Smart Electric Drive. We don’t know what the Ricci brothers are planning, but a video at Bertone’s new website and an Instagram account tell us, “The timeless icon is reborn.”

The Bertone Nuccio was the firm’s final concept before bankruptcy, a 100th anniversary celebration that attempted to combine Bertone’s hallmark flourishes into a wedgy berlinetta without much success. This new effort looks more promising. Based on the coupe in the teased image, we’ll expect something supercar-ish. Based on the rear diffuser design in the teaser video and what could be two elongated exhaust ports, it’s possible there’s an internal combustion engine behind the cockpit. The arrowhead side vent recalls the 1968 Alfa Romeo Carabo and 1970 Lancia Stratos Zero concepts, both just as important as any of the roadgoing cars. And the video reveals a ton of detailing, especially around the LED headlights and taillights and the wheels.

This year being Bertone’s 110th anniversary and “110” featuring prominently in the teasers, it shouldn’t be long before we find out what “The dawn of a new era for contemporary Bertone” means.

Zenvo TSR-GT ends the TSR range with a 263-mph top speed

The Danes aren’t known for being flashy, which helps explain how Danish supercar maker Zenvo has been building and selling 1,000-horsepower, million-dollar coupes since the ST1 in 2008. Zenvo introduced the latest evolution of its single product in 2016, the TSR. Next year, the TSR will be replaced by an all-new model, so the company developed an end-of-life special called the TSR-GT to mark the milestone. The TSR-GT joins the TS1 GT and TSR-S trims on the same base platform, the last of which we saw in 2018 showing off its highly unconventional Centripetal Wing. The TSR-GT makes no unexpected gestures, its remit to be fast and comfortable (for a hypercar).

The first step in the achievement is more horsepower. In-house engineers developed a Power Pack for the 5.8-liter twin-supercharged flat-plane-crank V8 consisting of a new intake plenum, manifold, and ECU tuning. Upgraded with a flex fuel sensor that adds E85 capability on top of regular pump fuel, output climbs from 1,177 horsepower to 1,360 hp.

Cutting through the air is easier thanks to the lack of a roof scoop intake, a longer, lower, fixed rear spoiler, and new aero wheel covers. Working in conjunction with the new final drive so the TSR-GT can stretch its legs further, top speed climbs from the 202 miles per hour of the TSR-S to 263 mph. That’s a little faster than the 250-mph McLaren Speedtail, a little behind the 273-mph Bugatti Chiron Super Sport 300+.

Interior comfort — as if any owner’s going to drive this like the GT in the name suggests — steps up by having leather replace naked carbon and Alcantara in places like the instrument panel, seats and steering wheel, finished with leather-trimmed velour floor mats that help reduce cabin noise.

Zenvo’s making just three TSR-GT’s, all of them sold. Whatever arrives to replace it next year is rumored to used a twin-turbo V12 and electric motors producing a combined 1,800 horsepower.

Corvette-based Chevrolet with ‘incredible performance’ coming in 2025

GM President Mark Reuss’ Investor Day presentation has been a font of information. Most of it’s been pretty straightforward, like the info about GM service centers working on Teslas and the GMC Acadia getting larger for its third generation. This one lives at the mysterious end of the foreshadowing pool. When discussing what’s in store for the Corvette, Reuss mentioned two vehicles. As reported by Fox News, the first is a straight-up Corvette trim, “the next version of the C8,” the “next-step in performance for Chevrolet” supposedly so good “you won’t be able to imagine it from a performance standpoint.” Since Reuss’ was reportedly talking about new vehicles due in 2024, he wouldn’t have been referring to the hybrid, all-wheel drive Corvette coming in 2023. The AWD hybrid could have been the trim referred to as the Corvette Grand Sport in a potentially leaked GM document from 2020. The powertrain in that coupe will be the 6.2-liter LT2 V8 from the base Stingray combined with electric motors driving the front axle to make somewhere around a combined 600 horsepower and 500 pound-feet of torque.

The images in Reuss’ presentation were obscured for media viewers, but we suspect he meant the ZR1. That supposed leaked doc said its due in 2024 with 850 hp and 825 lb-ft. Output will come from an LT7 engine that’s already on the testing bench if a recent clue found at the National Corvette Museum can be believed.

What will follow that is a car Reuss called an “incredible performance car” that he expects to “put the world on notice” as to what GM is capable of and “set the standard of the world for performance for Chevrolet.” Based on the trim cadence we’ve been covering for years, this sounds like the Corvette rumored to be called the Zora, which would pair the twin-turbo LT7 V8 with electric motors for more than 1,000 hp. However, Reuss didn’t call this car a Corvette; he only said it would be based on the C8 architecture. Back to that 2020 GM document, it had the ZR1 coming in 2025. That’s a year later than this mystery offering, and we can’t imagine why Reuss wouldn’t call a Corvette a Corvette.

In a LinkedIn post from April that provided video of next years AWD Corvette, Reuss wrote, “we will offer an electrified and a fully electric, Ultium-based Corvette in the future.” On that note, the only unaccounted for Corvette family vehicles we’re aware of in the rumor pipeline are the electric Corvette-inspired crossover as part of Project R, and the electric Corvette sedan said to be coming mid-decade. So stay tuned, big electric things are coming from Chevrolet.

Related video:

2023 Audi R8 to be the 17th and last year for the super coupe

In October, Audi introduced us to the final special edition for the R8, the 2023 Audi R8 V10 GT RWD. This was the second coming of the GT name to the Audi lineup, following the 2012 Audi R8 V10 GT. Audi limited the previous car to 333 coupes and 333 Spyders. The new GT will only get 333 coupes, R8 technical manager Nils Fischer telling CarBuzz there isn’t enough overall R8 production left to squeeze in a Spyder. The Ingolstadt automaker figures to build about 2,000 R8s at for the 2023 model year, then the R8 is dead after two generations and 17 years on the market. As it stands, there’s no successor anywhere near ready to go. Fischer told Car and Driver the details of a next-gen car are still being sorted out.

The consensus has been there’s something electric headed for the top spot. Audi produced a very short lived electric R8 E-Tron with the second-gen R8, selling just 100 examples in a year before pulling the plug. As EVs became the thing, rumors of another electric R8 persisted. Sometimes the rumors were spun from conceptual cloth, like then when Audi showed the PB18 E-Tron Concept in 2018. Sometimes these were spun from unnamed insiders, like the 2019 prediction that there would be an R8 E-Tron GTR based on the Porsche Taycan’s platform. Sometimes they came from executive statements, like when a brand VIP told Automotive News in 2021 an R8 EV “won’t just be an R8 with an electric motor,” it would be, rather, “an R8 but different.” And sometimes whispers from “Audi insiders” got the rumor spigot going again, like when Autocar wrote in September of this year that “the supercar has not yet been officially signed off but is very much underway” and won’t be called R8 nor look like the R8, and when Car and Driver wrote a month later the car is codenamed Rnext and has been pushed back to 2029.

Even the powertrain is up in the air, apparently, thanks to the European Union leaving a door open to synthetic fuels for now. An Audi project manager has already said he believes the ICE could survive past 2030 in Europe. On top of this, all the shuffling going on at the VW group with respect to personnel, platforms, software, and tentpole product initiatives like Project Trinity tend to reduce visibility to just beyond arm’s length. The only sound bet is that there will be something to occupy the halo spot sometime before the end of the decade.

Meanwhile, start saving your Christmas card money. The Audi R8 V10 Performance RWD starts at about $162,000 in the U.S., and it’s going, going, almost gone.

Mercedes-AMG One sets Nurburgring record, could’ve gone faster: Watch the run

In September 2018, Mercedes-AMG claimed it didn’t see the point of using the One to set a new record on the Nürburgring. It has obviously changed its mind: The Formula One-derived hypercar just set a new record for street-legal production cars on Germany’s grueling track.

DTM pilot Maro Engel lapped the Green Hell in 6.35.183 on October 28, though the record wasn’t announced until now. In comparison, the Porsche 911 GT2 RS MR logged a time of 6:38.835 in June 2021, and the Mercedes-AMG GT Black Series took 6:43.616. It sounds like the One could have been even quicker in better weather conditions: AMG explained that the track was damp and slightly dirty.

Mercedes made no modifications to the One to set the record; if it had, it wouldn’t be eligible to claim the production car crown. The company notes it dialed in the maximum camber values before letting Engel loose on the track, however. The car’s gasoline-electric hybrid drivetrain consists of a turbocharged, 1.6-liter V6 engine and four electric motors. The system is closely related to the one that powers AMG’s championship-winning Formula One car, and it delivers 1,063 horsepower in this application. While setting a record with this much power might sound easy, Engel stresses it’s quite difficult. He notably had to make the most of the brake energy recuperation system.

“We tried to find the optimal deployment strategy during the pre-tests. Like Lewis Hamilton and George Russel on their race weekends, I also had to deploy the electrical energy of the hybrid drive in the best possible way. That’s not easy, especially with this length of track,” he said. He ultimately selected the “Race Plus” driving mode that provides the best possible aerodynamic profile and lowers the ride height.

Records are meant to be broken. While the One’s is seriously impressive, we can’t help but wonder who will manage to beat it.

Related video:

2023 Chevrolet Corvette Z06 production numbers increased

The headlines say Chevrolet has re-opened order books for the 2023 Corvette Z06 after closing them in July. Those headlines should come with asterisks. What the small print explains — and should have always explained, even here — is that GM gatekeepers lowering the drawbridge means practically nothing for anyone who didn’t get on a dealer list a long time ago. When GM stopped taking orders in July, it stopped taking names off of dealer’s lengthy lists of reservation holders. The production process seems to be going better than planned, so “re-opening the order books” means GM has increased the number of cars it plans to build for the 2023 model year and has asked dealers to submit more names for orders to fulfill. A GM spokesperson told Motor1, “We had previously shared with dealers and the public that we had accepted enough Z06 orders to fill the number of Z06 production slots we had for calendar year 2022, so we stopped elevating dealer orders to accepted orders that the plant would build. Now we are saying we’re going to accept more dealer orders to continue filling the pipeline of Z06 production through the end of model year 2023.”

We don’t have any details to explain any of this nor put it in context. GM didn’t reveal its initial production estimate, and it hasn’t said how many orders it will add to the previous mysterious number. It was thought GM’s conservative production window had to do with a supply constraint, but even that’s not clear. We don’t know how many reservations there are, either, although a thread at Mid-Engined Corvette Forum lists more than 100 dealers and suggests just eight of them have easily more than 6,000 reservations combined. One dealer would only say its reservation list was “out to 2025.”

GM built 39,940 of the C7 Z06 from 2014 to 2019, averaging a touch under 8,000 units per year. Dealers know this, so for one to say they’re booked until 2025, the order rolls must be relatively staggering. There’s no reason for dealers to be in a hurry to get cars built, either, with some charging anywhere from $35,000 to $100,000 over the base $106,395 MSRP per vehicle according to posters.

As for verified production, Corvette Blogger wrote a week ago that 41 customer Z06 orders have been built as of the end of October, 22 of them the 70th Anniversary Editions. On top of that, it’s said 216 Z06s have been built for GM’s Captured Test Fleet used for proving and data capture. The first customer deliveries have been made, including Rick Henderson acquiring the first one off the line, a Carbon Flash 70th Anniversary Edition he bought for $3.6 million at a charity auction in January of this year.

Maurizio Reggiani talks racing, forced induction, and Lamborghini V12s

Maurizio Reggiani deserves his own chapter in Lamborghini’s history.

He joined the Italian company in 1995 and rose to the position of chief technical officer in 2006; he notably led the development of some of Lamborghini’s greatest modern-day engines, including the 6.5-liter V12 that powers the Aventador. His time as the head of Lamborghini’s research and development department ended earlier in 2022 and he now serves as vice president of motorsport. His successor, Rouven Mohr, is tasked with implementing an ambitious and far-reaching electrification strategy called Direzione Cor Tauri and outlined in 2021.

As Lamborghini prepares to enter a new era, I sat down with Reggiani for a behind-the-scenes look at nearly 30 years of V12 development.

[The following has been edited for clarity.]

RG: Lamborghini has made other engines and other companies have made V12s. Why is the V12 so often associated with Lamborghini?

MR: In a time when everybody started talking about downsizing and reducing cylinder count, we continued to say that the V12 is the flagship of the super-sports car. We were born with this: Lamborghini has made a V12 during every year of its history. We also did V8s in the time of the Jalpa, for example, but the V12 was every time the main pillar of this company. If you want to be considered the pinnacle of super-sports cars, no other engine can really speak to purists like a naturally-aspirated V12 can. In terms of power, in terms of sound, in terms of emotion, and in terms of, let me say, the coolest engine that’s possible in terms of engineering definition.

RG: What projects have stood out to you during your time at the head of Lamborghini’s R&D department?

MR: When I started my career, 40 years ago at Maserati, I worked in engine development. At Bugatti, I was responsible for powertrain, which of course includes the engine. For me, an engine is kind of like a first love, and you remain in love for all of your life. To look at an engine, to look inside, to discuss the components, to have an opinion, and to give a suggestion was my way of working every time.

One of the projects that excited me the most was the Diablo GT. For the first time, we decided to put a single throttle per cylinder, and it was a level of sophistication that was more or less never used before by Lamborghini. You take experience from the past and try to apply it to [the present]. This improved a lot the performance, and it was really super exciting. The engine in the Aventador is another highlight: it was designed together with the Aventador. That was a completely new car, we started from scratch, and you can imagine how exciting that was.

RG: You’ve taken the V10 racing; why not race a V12?

MR: We had a big discussion about this when we first started out in racing. We initially launched a one-make series in 2009, and after that we decided to also engage in the GT3 series, and the main point of discussion was that in every competition related to GT you have a balance of performance. There’s no sense to take on the weight and packaging of the V12 if after you need to put a restrictor that penalizes a lot of the performance. We decided the best compromise in order to match the balance of performance was the V10. At the end, you need to take an engine where even with the balance of performance you are close to maximum power. If you take an engine with a big output and you move its curb of efficiency to a lower part [of the graph], you cannot be competitive.

RG: Was adding forced induction, whether it’s a turbocharger or a supercharger, ever considered?

MR: We never [used forced induction] because our vision was that the sound of the V12, the frequency of the V12, cannot be done with a turbo. Clearly, today you have so many filters in the exhaust system that the sound is reduced. That are new rules that came from California where you cannot exceed a given decibel during the test. Years ago it was only in the default [driving] mode; now in all of the modes you need to be below a certain level. It’s important to maintain the frequency of the sound.

Also, the power was, let me say, enough. We reached 350 kilometers per hour (about 217 miles per hour) with the Aventador SVJ. We put much more attention to the use of the power and the shape of the torque curve because we were sure this is what customers ask. We want to give the V12 a response that’s as similar as possible to a motorcycle’s. On a motorcycle, when you twist the accelerator you have the impression that the engine is able to catch 10,000 RPM *snaps* like this. In a V12, which is a big engine, the enemy is to be able to move up and down [the rev range] as quickly as possible. This depends a lot on the weight of the pistons, the connecting rods, the crankshaft, and of course electronics. You need to tune everything as much as possible and what gives this perception is the sound you hear.

RG: I spoke to you about carbon fiber connecting rods in 2016. What happened to that project?

MR: The parts were done in Seattle, at the University of Washington. The complexity in terms of the materials used, the necessity to have metal inside, and the difficulty of bolting the connecting rods because you need to put an insert inside of them [were issues]. And, after that you have dilatation. We built a prototype and tested it but it remained at the research level. We have several examples of development work that run, but at the end every time you need to do a decision sheet where you decide economics, reliability, reproducibility, and cost, and what we work on in R&D can’t reach production every time.

RG: What should we expect from the next V12?

MR: The V12 is part of Lamborghini’s DNA. We already announced the Aventador’s successor will keep the naturally-aspirated V12, though it’s a V12 that is radically new compared to what we have today. We use this new engine to correct some of the peculiarities that can be related to the weight and that can be related to the RPM in order to have the best level of thermal dynamics coupled with a hybrid system.

Related Video

Ferrari lifts profit forecast after strong Q3, keeps cautious stance on margins

MILAN — Luxury sports car maker Ferrari said on Wednesday it was improving its forecasts for full-year results, including for core earnings, after beating expectations in the third quarter, supported by a double-digit increase in shipments.

The company however struck a more cautious tone on the margin on those core earnings, now seen at around 35% for this year, versus a previous guidance of over 35%.

It said industrial costs and research and development expenses increased in the past quarter mainly due to higher depreciation and amortization and cost inflation.

Ferrari said its adjusted earnings before interest, tax, depreciation and amortization (EBITDA) would grow this year to over 1.73 billion euros ($1.71 billion), versus an already improved forecast of 1.70-1.73 billion euros it provided three months ago.

After briefly turning positive following the release of the results, Milan listed shares in Ferrari fell as much as 2.4%. By 1235 GMT they were down 1.4%.

In the third quarter, adjusted EBITDA rose 17% to 435 million euros, topping analyst expectations of 418 million euros, according to a Reuters poll.

($1 = 1.0107 euros)

(Reporting by Giulio Piovaccari; Editing by Keith Weir)

Related video: