Five Exotic Car Technologies You’ll See On ‘Regular’ Cars Within 5 Years

Supercars – and more recently, a new class of Hypercars – continue to showcase the very best and most advanced technologies currently available in production road cars. While that’s not going to change (it’s the natural order of things, really), we should be anticipating an influx of exotic and wild features on the common vehicles of tomorrow.

The top-down succession of technologies has been occurring since the dawn of automobiles; however, with the exponential rate at which technology is improving these days, it won’t be inconceivably long before your average commuter car will be boasting many of today’s supercar credentials.

The proliferation of EV technology adds yet another dimension to this communal melting pot of automotive prosperity, where we’re already seeing once unimaginable horsepower and torque figures become quite easily attainable – not to mention all the other groundbreaking advancements in aerodynamics, hybrid technologies, software, and more.

Here are Five Exotic Car Technologies You’ll See On ‘Regular’ Cars Within 5 Years.

Active Aerodynamics

Disclaimer: I am fully aware that advanced aerodynamic technologies (of which active aero is certainly a part of) will be overkill for the majority of production road cars, both now and in the future.

However, we can certainly expect it to start featuring more regularly on flagship performance models – particularly those from mainstream producers – within the next few years. In fact, it has been basically confirmed that the new 992-generation Porsche 911 GT3 RS will have at minimum, an actively-adjusted rear wing. Ok, so Porsche isn’t exactly your typical “mainstream” automaker, but there’s no reason we won’t see similar adaptations on next-gen versions of cars such as say, the Honda Civic Type R, Ford Mustang Shelby GT500 and Nissan GT-R.

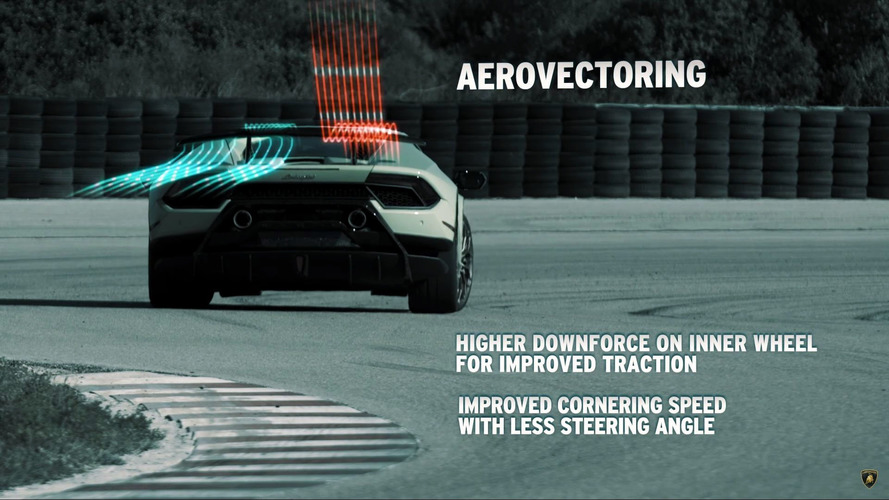

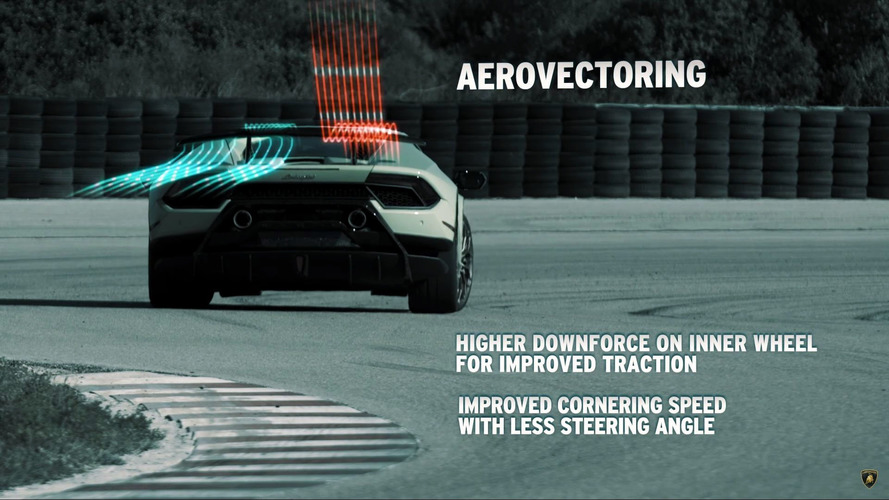

By the way, active aerodynamics can (and should) involve a lot more than just a rear wing that changes its position at certain speeds. We’re talking more along the lines of the Lamborghini Aventador SVJ’s ALA 2.0 system, which controls actuators that open and close flaps on the front splitter, engine cover and rear wing. In conjunction with Lamborghini ‘Dinamica Veicolo Attiva’ 2.0, the SVJ’s computer processors are able to determine where downforce is needed in live time.

In the same way that some cars have torque vectoring, this essentially provides the Aventador SVJ with “aero” vectoring. That is, the ability to actively manage the car’s non-static aerodynamic features to improve cornering speeds and stability with minimal adjustments to steering and pedal inputs. For example, on your typical turn, having more grip (and hence, more downforce) on the inside wheels will improve turn in. Flaps on the front splitter and rear wing will be adjusted by the system to decrease relative downforce over the outside turning wheels, creating a grip bias towards the inside. Aided by other features such as rear-wheel steering, this can significantly improve the car’s general handling capabilities.

Supercapacitors

It’d be prudent to first speak about what supercapacitors basically are, before getting into the the nitty-gritty of how they fit into the general automotive landscape – so let’s do that. After all, the likelihood is that most people don’t know what they are, and the fact of the matter is that they’re not currently a hot topic in any of the broader conversations about EVs or hybrids. So that was your first clue: it’s some sort of electrical thing-a-ma-jig. Its present application is predominantly in that of hybrid technology, storing energy which can be converted into thrusting the car forward. If this sounds to you like what your typical EV battery does, you’re definitely on the right track. However, that’s where the similarities end.

First of all, capacitors are hardly a new technology – they’ve literally been around since electricity – nor are the proprietary to automobiles. In fact, most of the gadgets we use today have them; smart phones, computers, stereos, or just about anything you can think of that has a circuit board. That’s because of their very crucial ability to store and release energy at a rapid pace, without suffering from degradation like a typical battery.

The Lamborghini Sián is the most notable example of an automobile which uses a supercapacitor – the ‘super’ added because, well, you need a really, really big capacitor to help power a car. In this configuration, the supercapacitor collects and stores energy (primarily from regenerative braking). In certain moments (such as a launch), the supercapacitor dumps all of its energy into an electric motor which immediately and briefly adds an extra 34 hp on top of what the Sián’s 785 hp naturally-aspirated V12 engine produces.

As long as the supercapacitor keeps getting recharged – which can be achieved with just seconds of hard braking – there will always be that extra bit of power boost at the car’s beckoning. Compared to an EV battery which takes much, much, longer to fully recharge, and weighs substantially more, you might be wondering why supercapacitors aren’t the dominating technology in electric or hybrid vehicles today.

Well, there are a few very important reasons for this. By nature, supercapacitors aren’t able to store energy for long periods of time like a battery, making them unviable to be the primary food source for an electric vehicle. At least for now, simply replacing a battery with a (mega?) capacitor isn’t the solution; they’re not going to be powering cars on their own, any time soon. On that note, the ‘wee-little’ 34-hp-producing supercapacitor in the Sián probably isn’t cheap either. However, we should expect that to change as the technology gets refined, eventually becoming scalable at mainstream levels.

I’m no engineer, but I figure these same principles could be applied to fully-electric platforms, with some sort of battery-supercapacitor amalgam creating a “best of both worlds” scenario. This means we could see more supercapacitors on everyday cars sooner than later, with the shift to EVs already well underway. Then there’s the concept of solid-state batteries too… but we’ll leave that one for another story.

Magnetorheological Suspension System

Magne-what? Modern automobile suspension technologies have also been put through perpetual rethinks throughout the years, significantly evolving from more humble beginnings with leaf springs and the like. Although there is still work to be done to realize the full potential of magnetorheological suspension systems, they do presently represent the current peak of suspension technology as far as handling performance is concerned; i.e. they’re good for go-fast automobiles like supercars and hypercars.

In principle, MR suspensions work very much the same as hydraulic suspensions in that they are filled with a fluid which travels between different chambers in the piston. This allows “shock” energy to be converted into heat, essentially absorbing impacts from road contact to improve ride quality and performance. The difference with an MR suspension is that it also incorporates an electric circuit into its piston assembly.

This is where the technology is revolutionary: the electrical currents supplied to the suspension create magnetic fields inside the piston, which can instantaneously change the properties of the fluids inside, subsequently altering how the suspension responds and behaves. Adaptive suspension systems rely on this process in order to calibrate the characteristics of the suspension in any given moment. Computers help monitor factors such as steering angle, g-forces, pitch and various other factors and decide on how best to optimize the geometry based on the data. Advanced systems are able to do this in real time, making calculations and adjustments at a rate of thousands of times per second.

While MR suspension systems do still face challenges – such as the dampers not being serviceable, while being prone to problems such as hysteresis, leakage and sedimentation – the technology continues to be refined. It’s destined to become a more common feature on the cars of tomorrow as things continue to improve and scale. If you like the idea of active aero, then MR dampers are basically what that is, but for suspensions. Imagine driving a car equipped with both such systems!

AI & Cloud-based Driver Aids / Monitoring Tech

When we think of ‘connectivity’ these days, we often refer to social media, various smartphone apps, zoom meetings and some degree of cloud computing. All of the aforementioned typically exist within the ecosystem of mobile devices and personal computers, but connectivity is starting to apply very much to automobiles too. Features such as GPS navigation, in-car Wi-Fi – and more recently, self-driving capability – immediately come to mind, but with the direction the industry is going, we can expect so much more than just those things.

Connectivity as we know it, is now a big part of how we get from one place to another – physically, as well as virtually. And you only need an imagination (albeit one rooted in reality) to conjure up some of the fascinating tech we’re about to see integrated into the everyday automobile. Real-time warning systems that can detect intricate anomalies or hazards using artificial intelligence? That’s already being developed by Porsche in partnership with HERE Technologies and Vodafone, and will feature a system which identifies animate objects, monitors the behavior of other drivers and anticipates inclement road conditions. Trials are currently taking place in Aldenhoven, Germany – using a Porsche Taycan amongst other vehicles – where the system will be further optimized before its rolled out to more test sites.

“5G and data processing on the roadside help to transmit hazard warnings without delay and make road traffic even safer,” Michael Reinartz, Director of Innovation at Vodafone Germany, said in a statement. “We are currently trialing this under everyday conditions.”

Rimac is working on an “AI Driving Coach” program, which should be ready before the first examples of its Nevera hypercar roll off the production line. This system uses, as its name implies, an artificial intelligence which guides drivers while they’re on a race track. Using visual and audio aids, the AI will give drivers real-time tips on how to improve their lap times. An “augmented-reality” racing line will even be available for a select group of renown international race circuits. The same AI system is also capable of providing self-driving features. Awesome.

“What we are building is a system where AI plays a key role in teaching the driver how to perform on racetracks, at the maximum vehicle performance,” Sacha Vrazic, Director of Rimac’s autonomous driving department explains. “Not all of our customers are professional drivers, but we want them to really enjoy the car and have fun with it.”

Michelin has recently released a new range of Pilot Sport Cup 2 tires, which work with their proprietary ‘Track Connect’ app to deliver unparalleled access to essential data related to a car’s handling, grip and the suitability of its tires. This data is then translated into advice for the driver with regards to optimizing tire pressures, inflation, temperatures and much more. It also provides inputs on the driver’s style, performance and skill, whether pushing the limits on the racetrack or simply commuting around town.

Naturally, the newest and most advanced technologies will typically debut on more expensive cars, before proven dependability and the economies of scale bring them to the mainstream. Expect the aforementioned technologies, and many more, to start featuring on a growing number and variety of automobiles.

Synthetic Bio Fuels (Hydrogen)

Even with the likes of Porsche taking the reigns on this recently (with McLaren and Audi also continuing to play major roles), bio fuels – or ‘eFuels’, as they’re calling it in Stuttgart – won’t require much of a trial period on exotic cars before being rolled out to the rest of the crowd; should eFuels proliferate as a viable alternative to power the world’s vehicles, it will undoubtedly benefit all players within the entire automotive landscape.

Porsche said its first iteration of Esso Renewable Racing Fuel is a blend of advanced biofuels, formulated from food waste products by ExxonMobil’s in-house team of scientists and engineers. The automaker has already begun experimenting with eFuels in its GT Cup race cars; so if it’s ultimately good enough for that level of performance, the assumption is that it will definitely suffice for production road cars as well.

The big-wigs at Porsche are already suggesting that this latest version of eFuels may even allow internal combustion cars to achieve a smaller overall carbon footprint than an electric car, particularly when taking into consideration, the byproducts created from battery manufacturing. “This technology is particularly important because the combustion engine will continue to dominate the automotive world for many years to come,” said Porsche R&D Executive, Michael Steiner. “If you want to operate the existing fleet in a sustainable manner, eFuels are a fundamental component.”

“Porsche is committed to three powertrains: purely electric, plug-in-hybrids, and highly efficient gasoline engines. From Porsche’s point of view, eFuels open up an opportunity for our plug-in hybrid models as well as our icon, the 911—either with a combustion engine or as a very sporty hybrid. This means that we could continue to drive the 911 for many years to come, which will certainly make our customers and fans happy.”

Without diminishing the significance or role that EVs will play in the more distant future – we should still expect them to become the prevailing technology – perhaps an optimally balanced coalition of clean burning fuels and fully-electric solutions is not only better for business, but for the environment too. It looks as though Porsche is already creating a model for how this could work, and if the science behind eFuels checks out, then there’s no reason that it couldn’t become the conventional formula in the years to come.