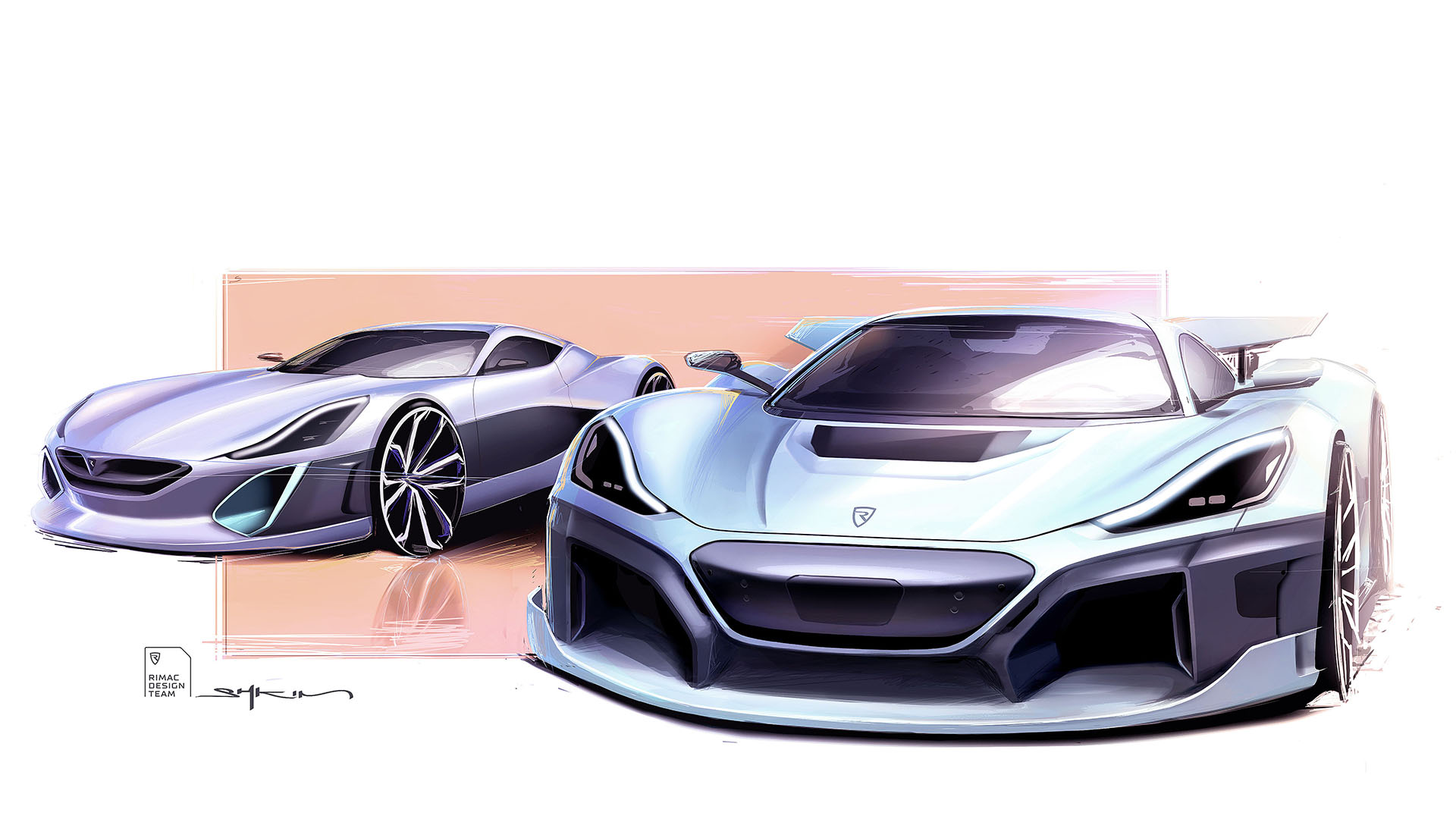

As Rimac continues to develop and homologate its electric C_Two, it has taken fans and interested parties along for a behind-the-curtain ride. Through a series of clips, the company has shown office and manufacturing tours, footage of its aerodynamic examinations, and recently, a teaser of the supercar crash testing. But that teaser didn’t show any actual impacts. This new one does, five times over.

Rimac, a brand Porsche and Hyundai have both partnered with and invested in, is aiming to make the C_Two available across all major markets in the world. It’s a lofty goal, as Rimac has to undergo the same homologation process as any other major manufacturer. That means meeting the same safety requirements, which requires repetitively crashing C_Two prototypes, each estimated to be worth more than $1 million. That type of cost is tough for low-volume manufacturers, so it’s of paramount importance that each test gleans as much information as possible.

A lot of digital testing has occurred for Rimac to get to this point. Engineers run millions of computer simulations and thousands of material and component tests before even building an experimental prototype. Then Rimac has to get the physical car to a point where its tests and results match the digital results.

In this video, the engineers detail one specific issue they came across. During front-end crash testing, part of the rail structure “peeled off like a banana,” seen at about 3:05. A problem such as this didn’t even show up in digital testing. Check out more on the process, and see Rimac crash its crown jewels into a wall.

Now that the first round of crash tests is successfully completed, we can proceed to the next stage of development with full confidence. The next step in the development of the C_Two is to further improve our design together with perfecting the correlations of our virtual simulations.